Four things you never knew about Dovetail Joints (plus one you probably did!)

At Back to Basics, all the drawers in our bespoke, hand-built kitchens and furniture are made using dovetail joints. Here’s why:

1. Not only do they look beautiful, but they also hold timbers together without the need for screws or nails. These days cabinet makers add glue for extra strength, but that’s a ‘just in case’ because the shape and fit of these clever joints are enough by themselves.

2. A dovetail is one of the oldest forms of joinery. This method of fixing pieces of wood together has been around for 3000 years, or more – first seen in Egyptian coffins and jewellery boxes. At Back to Basics we are all about keeping the tradition alive in modern ways.

3. Furniture historians use dovetail joints as a mark of the skill and craftsmanship of the cabinet maker. Back to Basics owner, Andrew Parsley, learned to hand-cut dovetails during his cabinet maker training 30 years ago, but is very glad that machines were invented to do the job much more quickly! Setting up the jig precisely is still vital though because the strength of the joint is dependent on the precision with which they are cut and fit together, as well as the angle.

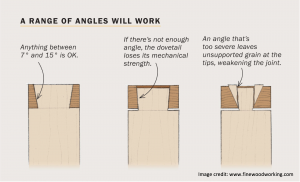

4. The angle of a dovetail joint should be between 7 and 15 degrees: too broad and the joint won’t be strong enough, too skinny, and the pin can snap. So the angle of the dovetail mainly depends on the use and wear the joint will get.

Diagram showing dovetail angles vs strength from Fine Woodworking

5. They are called ‘dovetails’ because they are shaped like the tail feathers of a dove!

Andrew Parsley cutting pins and tails for dovetail joints using a router and jig.